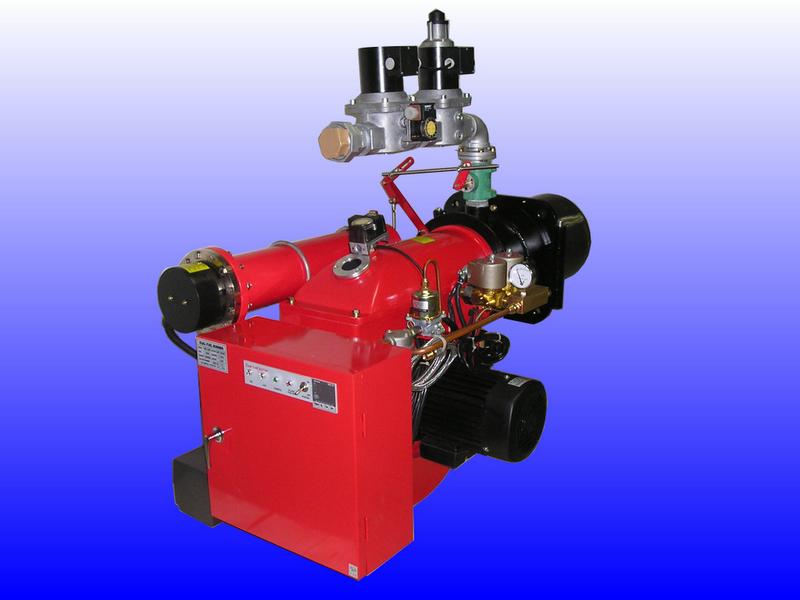

PG系列中小型双段火燃气燃烧器

以天然气(NG、LNG)、液化石油气(LPG)作为燃料,全自动双段火(大、小火)方式控制,可根据设备负荷控制进行大/小自动切换,满足较高精度负荷控制需求。

广泛应用于中小型锅炉、加热炉、喷涂设备、烘干设备、热处理设备等热能设备,实现有一定负荷控制精度要求的应用。

一.安全可靠的全自动程序控制

1. 全自动程序控制运行,可根据负荷参数设定控制大/小火切换,实现出力大小的自动控制;

2. 采用离子感应或UV紫外监测装置实现意外熄火保护功能,保证火焰燃烧安全稳定;

3. 配置燃气压力和空气压力安全保护开关,同时可方便地实现外部连锁控制,确保运行安全;

二.良好的燃烧性能

1.大/小火状态燃烧量在处理范围内可自由设定,负荷输出控制更灵活方便;

2.大/小火切换时风量可根据设定自动同步调节,保证大/小火状态下都实现最佳燃烧状态;

三.可灵活增加的配置

1.可通过增加配置比例式调节装置实现中小型燃烧器的比例控制,满足更高精度负荷控制的要求;

2.可通过增加配置燃气调压和过滤装置适应不同的起源供应方式;

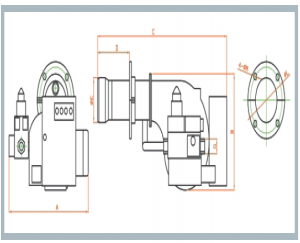

|

型号

|

A

|

B

|

C

|

D

|

E

|

G(/N,/L,/C)

|

L

|

M

|

||

|

PG23W

|

550

|

375

|

610

|

100-240

|

133

|

1”

|

1”

|

--

|

165-195

|

12(M10)

|

|

PG40W

|

655

|

430

|

950

|

150-350

|

170

|

1 1/2”

|

1”

|

1 1/2”

|

185-225

|

14(M12)

|

|

PG60W

|

780

|

515

|

1205

|

170-400

|

170

|

1 1/2”

|

1”

|

2”

|

185-225

|

14(M12)

|

|

PG80

|

780

|

515

|

1270

|

220-440

|

205

|

1 1/2”

|

1 1/2”

|

2”

|

240

|

18(M16)

|

|

PG100

|

780

|

515

|

1295

|

220-440

|

230

|

1 1/2”

|

1 1/2”

|

DN65

|

276

|

18(M16)

|

|

PG120

|

830

|

530

|

1350

|

240-460

|

230

|

2”

|

1 1/2”

|

DN65

|

276

|

18(M16)

|

|

PG150

|

830

|

530

|

1450

|

240-460

|

230

|

2”

|

1 1/2”

|

DN80

|

276

|

18(M16)

|

|

PG200

|

985

|

860

|

1480

|

300-500

|

190

|

2”

|

1 1/2”

|

DN80

|

240

|

18(M16)

|

|

PG250

|

985

|

890

|

1480

|

300-500

|

190

|

DN65

|

2”

|

DN100

|

240

|

18(M16)

|

PG系列中小型双段火燃气燃烧器技术参数

|

型号

|

PG23W/N

|

PG40W/N

|

PG60W/N

|

PG80/N

|

PG100/N

|

PG120/N

|

PG150/N

|

PG200/N

|

PG250/N

|

||

|

输出功率

|

Kw

|

93-267

|

174-464

|

232-696

|

348-928

|

464-1160

|

580-1392

|

696-1740

|

812-2320

|

928-2900

|

|

|

万Kcal/h

|

8-23

|

15-40

|

20-60

|

30-80

|

40-100

|

50-120

|

60-150

|

70-200

|

80-250

|

||

|

控制方式

|

全自动双段火控制(可接受比例控制方式调节订货)

|

||||||||||

|

适用燃气

|

天然气(NG、LNG)

|

||||||||||

|

标准入口压力

|

Pa

|

2000

|

5000

|

||||||||

|

MmH2O

|

200

|

500

|

|||||||||

|

适应压力

|

Pa

|

1500-5000

|

4000-10000

|

||||||||

|

MmH2O

|

150-500

|

400-1000

|

|||||||||

|

设计燃料低热值

|

MJ/NM3

|

35.53(8500Kcal/Nm3)

|

|||||||||

|

适应环境温度

|

摄氏度

|

-15~60

|

|||||||||

|

火焰监测方式

|

电离型

|

UV紫外型

|

|||||||||

|

适用电源

|

AC220V

|

AC380V

|

|||||||||

|

电机功率

|

KW

|

0.25

|

0.55

|

1.1

|

1.5

|

2.2

|

2.2

|

3.0

|

4.0

|

4.0

|

|

|

防护等级

|

IP

|

40(可根据订货要求提高)

|

|||||||||

|

安装法兰形式

|

滑动可调式法兰

|

||||||||||

|

助燃空气量调节方式

|

同步伺服电动调节

|

||||||||||

|

燃气入口接口尺寸

|

1”

|

1 1/2”

|

1 1/2”

|

1 1/2”

|

1 1/2”

|

2”

|

2”

|

2”

|

DN65

|

||

|

型号

|

PG23W/N

|

PG40W/N

|

PG60W/N

|

PG80/N

|

PG100/N

|

PG120/N

|

PG150/N

|

PG200/N

|

PG250/N

|

||

|

输出功率

|

Kw

|

93-267

|

174-464

|

232-696

|

348-928

|

464-1160

|

580-1392

|

696-1740

|

812-2320

|

928-2900

|

|

|

万Kcal/h

|

8-23

|

15-40

|

20-60

|

30-80

|

40-100

|

50-120

|

60-150

|

70-200

|

80-250

|

||

|

控制方式

|

全自动双段火控制(可接受比例控制方式调节订货)

|

||||||||||

|

适用燃气

|

液化石油气(LPG)

|

||||||||||

|

标准入口压力

|

Pa

|

2800

|

5000

|

||||||||

|

MmH2O

|

280

|

500

|

|||||||||

|

适应压力

|

Pa

|

2000-5000

|

4000-10000

|

||||||||

|

MmH2O

|

200-500

|

400-1000

|

|||||||||

|

设计燃料低热值

|

MJ/NM3

|

100.32(24000Kcal/Nm3)

|

|||||||||

|

适应环境温度

|

摄氏度

|

-15~60

|

|||||||||

|

火焰监测方式

|

电离型

|

UV紫外型

|

|||||||||

|

适用电源

|

AC220V

|

AC380V

|

|||||||||

|

电机功率

|

KW

|

0.25

|

0.55

|

1.1

|

1.5

|

2.2

|

2.2

|

3.0

|

4.0

|

4.0

|

|

|

防护等级

|

IP

|

40(可根据订货要求提高)

|

|||||||||

|

安装法兰形式

|

滑动可调式法兰

|

||||||||||

|

助燃空气量调节方式

|

同步伺服电动调节

|

||||||||||

|

燃气入口接口尺寸

|

1”

|

1”

|

1”

|

1 1/2”

|

1 1/2”

|

1 1/2”

|

1 1/2”

|

1 1/2”

|

2”

|

||

英文介绍:

PGseries ofsmallsingle sectiongas burners

Natural gas (NG, LNG), liquefied petroleum gas (LPG) as fuel; automatic on / off control single section.

Applicable to small and medium sized boilers, water heaters, stove, paint rooms, paint equipment, die-casting machine, drying equipment, heat treatment equipment and other small energy equipment. It’s easy to install and economical.

一.Safe and reliableautomaticprocess control

1. Automatic control of operation, automatic monitoring, equipped with safe control system.

2. It’s automatic start / stop depends on the parameters such as temperature or pressure of the device, load control is simple and convenient;

3. Equipped gas valve with safety switch and flow control features to ensure the safety of gas supply and cut off;

4. Ion sensing flame monitoring device with unexpected flameout protection and ensure security and stability of flame;

5. With gas and air pressure protection switch, external control connections can be achieved easily and ensure safe operation.。

二.Good combustionperformance, easy maintenance

1. Air mixed design to ensure the combustion stability, security and adequacy;

2. Combustion volume and the amount of combustion air power range can be adjusted, output control and good combustion can be achieved through this adjustment;

3. Combustion head and steady flame burning device assemblies, without removing the burner, you can easily remove the internal components of maintenance;

4. Sliding mounting flange, the installation of combustion cylinder length can be adjusted, Non-standard lengths are also available to suit different furnace structure models;

Technical parameters of PGseries ofsmallsingle sectiongas burners

|

Model

|

PG6/N

|

PG10/N

|

PG17/N

|

PG26/N

|

PG40/N

|

PG60/N

|

|

|

Output Power

|

KW

|

23-70

|

46-116

|

81-197

|

116-302

|

174-646

|

232-696

|

|

104kcal/h

|

2-6

|

4-10

|

7-17

|

10-26

|

15-40

|

20-60

|

|

|

Control

|

ON-OFF

|

||||||

|

Fuel

|

NG、LNG

|

||||||

|

Gas pressure

|

Pa

|

2000

|

|||||

|

MmH2O

|

200

|

||||||

|

pressure range

|

Pa

|

1500-5000

|

|||||

|

MmH2O

|

150-500

|

||||||

|

Calorific value

|

MJ/NM3

|

35.53(8500Kcal/Nm3)

|

|||||

|

Temperature

|

degree Celsius

|

-15~60

|

|||||

|

Power Source

|

AC220V/50HZ

|

AC380V/50HZ

|

|||||

|

Motor

|

KW

|

0.12

|

0.18

|

0.18

|

0.25

|

0.55

|

1.1

|

|

Security Level

|

IP

|

40

|

|||||

|

Mounting flange

|

Slidingadjustableflange

|

||||||

|

Connection Size

|

3/4”

|

3/4”

|

3/4”

|

1”

|

1 1/2”

|

1 1/2”

|

|

|

Model

|

PG6/L

|

PG10/L

|

PG17/L

|

PG26/L

|

PG40/L

|

PG60/L

|

|

|

Output Power

|

KW

|

23-70

|

46-116

|

81-197

|

116-302

|

174-464

|

232-696

|

|

104kcal/h

|

2-6

|

4-10

|

7-17

|

10-26

|

15-40

|

20-60

|

|

|

Control

|

ON-OFF

|

||||||

|

Fuel

|

LPG

|

||||||

|

Gas pressure

|

Pa

|

2800

|

|||||

|

MmH2O

|

280

|

||||||

|

pressure range

|

Pa

|

2000-5000

|

|||||

|

MmH2O

|

200-500

|

||||||

|

Calorific value

|

MJ/NM3

|

35.53(8500Kcal/Nm3)

|

|||||

|

Temperature

|

degree Celsius

|

-15~60

|

|||||

|

Power Source

|

AC220/50HZ

|

AC380/50HZ

|

|||||

|

Motor

|

KW

|

0.12

|

0.18

|

0.18

|

0.25

|

0.55

|

1.1

|

|

Security Level

|

IP

|

40

|

|||||

|

Mounting flange

|

Slidingadjustableflange

|

||||||

|

Connection Size

|

3/4”

|

3/4”

|

3/4”

|

3/4”

|

1”

|

1”

|

|

责声明:以下信息由企业自行提供,内容的真实性、准确性和合法性由发布企业负责。锅炉信息网对此不承担任何保证责任。